Topsoil Filled MSE Bagwork

Simple, Clean & Environmentally Acceptable

Topsoil Filled MSE Bagwork

What is Topsoil Filled MSE Bagwork?

Soil filled mechanically stabilised earth (MSE) bagwork has been around for approximately 15 years in its current form and there are a number of comparable products on the market. In general, they all consist of geotextile bags containing typically free draining sandy soils for the construction of earthworks such as riverbanks, slopes and walls. In addition to the fabric bags, an integral component to the bagwork is the inclusion of spikes, pins or plates between the rows of bagwork which prevent slippage or movement of the bags.

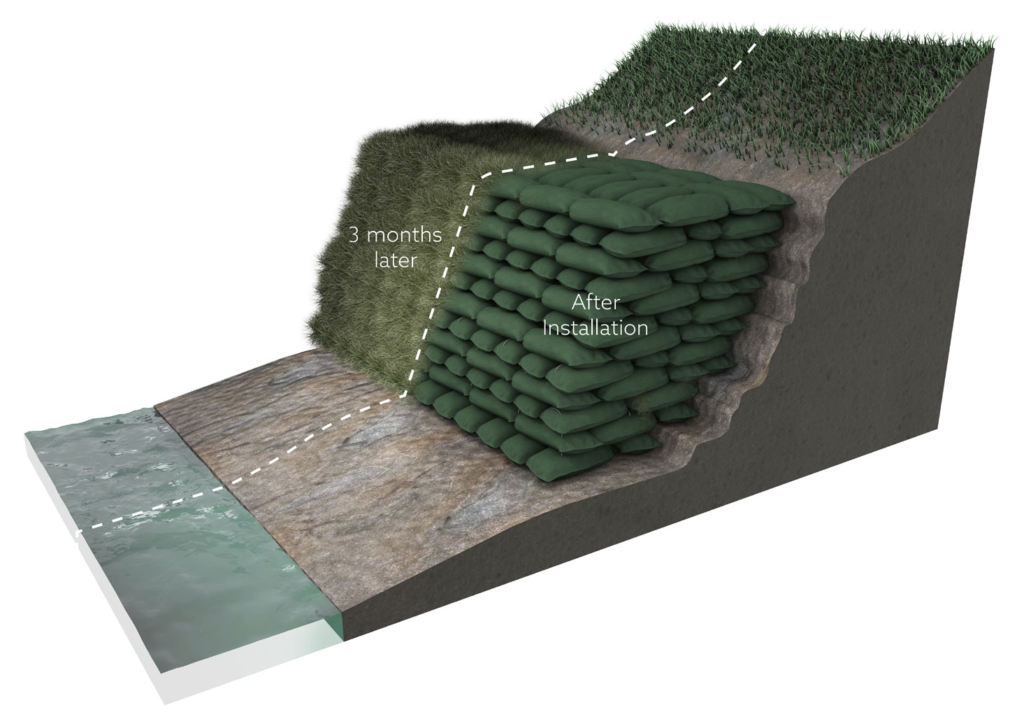

The characteristics of the geotextile bags, coupled with the soil that the bags contain, allow for the establishment and promotion of vegetation growth, both on and inside the bagwork. This not only greens up the bagwork to improve its appearance, it also strengthens the bagwork structure and improves both riverbank habitat and biodiversity.

As a form of construction, soil filled MSE Bagwork is very simple, requiring, in many cases, little or no specialist plant and no need for skilled labour. It is often a very cost effective, environmentally safe and ecologically beneficial form of riverbank, slope or wall construction.

MSE Bagwork Product Datasheet

For the construction of earthworks such as riverbanks, slopes and walls.

Topsoil Filled MSE Bagwork

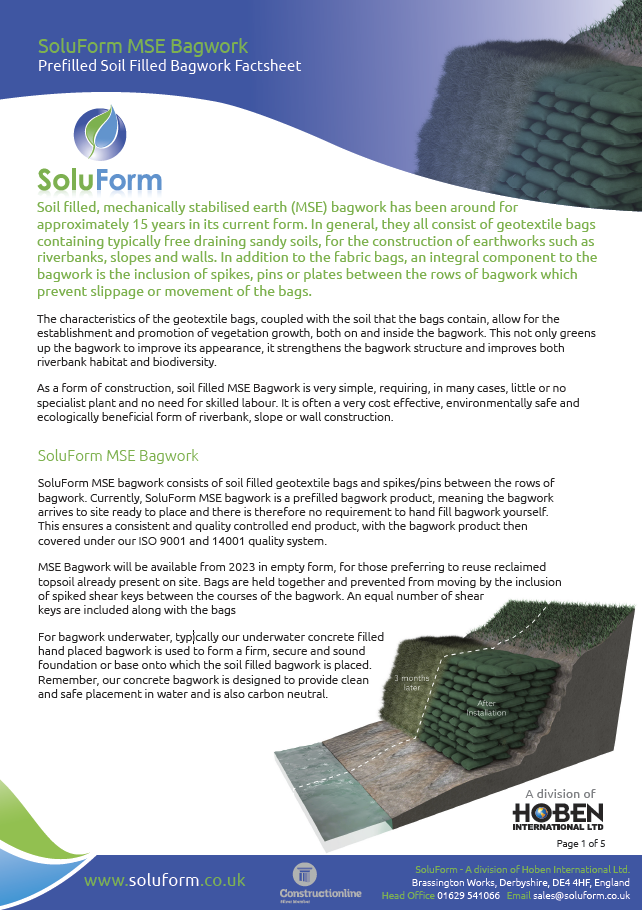

As with all forms of MSE Bagwork, SoluForm MSE bagwork consists of soil filled geotextile bags and spikes/pins between the rows of bagwork. SoluForm MSE bagwork is a prefilled bagwork product, meaning the bagwork arrives to site ready to place and there is therefore no requirement to hand fill bagwork yourself. This ensures a consistent and quality controlled end product, with the bagwork product then covered under our ISO 9001 and 14001 quality system.

Bags are held together and prevented from moving by the inclusion of spiked shear keys between the courses of the bagwork and an equal number of shear keys are included along with the bags.

For bagwork underwater, typically our underwater concrete filled hand placed bagwork is used to form a firm and secure base onto which the soil filled bagwork is placed. This is different from other suppliers who often rely upon gravel filled bagwork, rock rolls or compacting the ground as a suitable based for soil filled bagwork.

Lined concrete bagwork is however a much sounder foundation for soil filled MSE bagwork, and remember, our concrete bagwork is designed to provide clean and safe placement in water. Our concrete bagwork is also carbon neutral and EPD certified.

What makes SoluForm MSE Bagwork different from other forms of MSE Bagwork?

There are many competing versions and suppliers of soil filled MSE bagwork in the UK. What makes SoluForm MSE Bagwork different is:

-

Smaller, Easier to Handle Bagwork

This is obviously linked to manual handling, making the bags easier and safer to handle on site. Although this then requires more bags and shear keys for a given volume of bagwork, we have reduced our prices to make SoluForm soil filled bagwork comparable on a cubic metre basis, with larger 40kg alternatives.

-

Better Soil

Our prefilled bags are prefilled with the highest quality BS 3882:2015 compliant sand rich topsoil. This provides a more nutrient rich soil, whilst still ensuring the bagwork is free draining.

-

More Practical Bag Dimensions

Importantly, the length of the bag is close to being twice the width. This allows for bagwork to be rotated and better fit together to form a consistent width to a wall.

-

Colour and Appearance

rather than black or beige coloured bags, our SoluForm Bagwork is dark green. Ultimately, with any form of MSE bagwork, the aim is to “green-up” and vegetate the bagwork, so having a green appearance from the offset seems the most logical approach.

Design Guidance

Please find below a number of standard designs for a range of common applications:

Design guidance documents are in Acrobat PDF format. If you wish to save these to your local computer, please right-click each link and select the ‘Save As’ option.

Assembly Instructions / How to Use prefilled SoluForm MSE Bagwork

Our filled MSE Bagwork is prefilled in the factory, so arrives ready to use and there is no requirement for site staff to fill on site. With a design and quantity in mind, the bagwork should be ordered in advance of the site work commencing. Typical lead times are 3-5 working days for quantities up to 10 pallets.

Each pallet is shrink wrapped to protect from rainfall during storage and each pallet will yield approximately 0.8m3 of in-situ or established MSE bagwork. Delivery can be made on curtain sided or rigid vehicles. Dedicated flat bed, Moffett and HIAB deliveries are also possible UK wide.

Ideally, the base onto which MSE bagwork is placed should be level, firm and if necessary, compacted. Stepped foundations can be considered where there is a desire to form level courses to the bagwork. Deeper foundations beneath bed level should also be considered in watercourses where the bed material is prone to erosion, or better still, foundations in rivers created with our hand placed Underwater Concrete Bagwork. These deeper foundations better protect the wall against scour and undermining.

The first row of bagwork: With the groundwork prepared, the first row of bags can be placed, carefully abutting each bag as close as possible to its neighbour. Bagwork can be orientated in stretcher or header orientation to suit the design or desired width of the wall. Remember, the bagwork is 300x650mm in size, so wall widths of 300mm, 600/650mm or 900mm etc., are typical. Bagwork should be placed in a neat and uniform arrangement patting level wherever necessary. 250mm long ground spikes and 300mm galvanised rebar pins can be utilised to then anchor the bottom row of bagwork to act as an additional shear key. With the bottom row placed, backfill can then be placed behind the bagwork to the top level of the bags.

Additional rows of bagwork: On the top of the lowermost row, place the spiked shear keys. These can either be placed in the centre of each bag, or across the junction between two bags, depending upon the design. The second row of bagwork can then be placed over the bottom row of bagwork according to the design or preferred layout, such that bagwork overlaps. Typically, for a single bag width, this would be in a simple stretcher arrangement.

Once the second row is placed, additional backfill can be placed behind the bagwork, building up again the fill material level with the top of the second row.

Additional rows can then be built up in the same way by placing the shear keys and bagwork, then backfilling behind the bags, row by row, to within 100mm (the final row) of the desired height of the wall. The backfill material should typically be compacted every two or three rows.

Should geogrid be required to strengthen and support the wall, this can be included, extending between the bagwork and the fill material behind the wall, held into position by the spiked shear keys or plastic spikes. The geogrid should be laid horizontally, pulled tight and the fill material compacted around the placed geogrid.

Final row of bagwork: Typically the final row of bagwork is placed in a header arrangement, such that a section of the top row of bagwork overlays the fill material behind the wall. This improves the structural integrity of the bagwork wall. Additional pins can be added to fasten the bagwork to the fill material behind the wall and often the rear section of bagwork is overlain with topsoil.

With the bagwork assembled, the final step is to include planting.

Planting is needed to vegetate the bagwork, improve bagwork integrity and protect the fabric long term. Our prefilled MSE Bagwork is not pre-seeded, as pre-seeding bags can create problems with storage and necessitates the use of the bags within 5 days of manufacture.

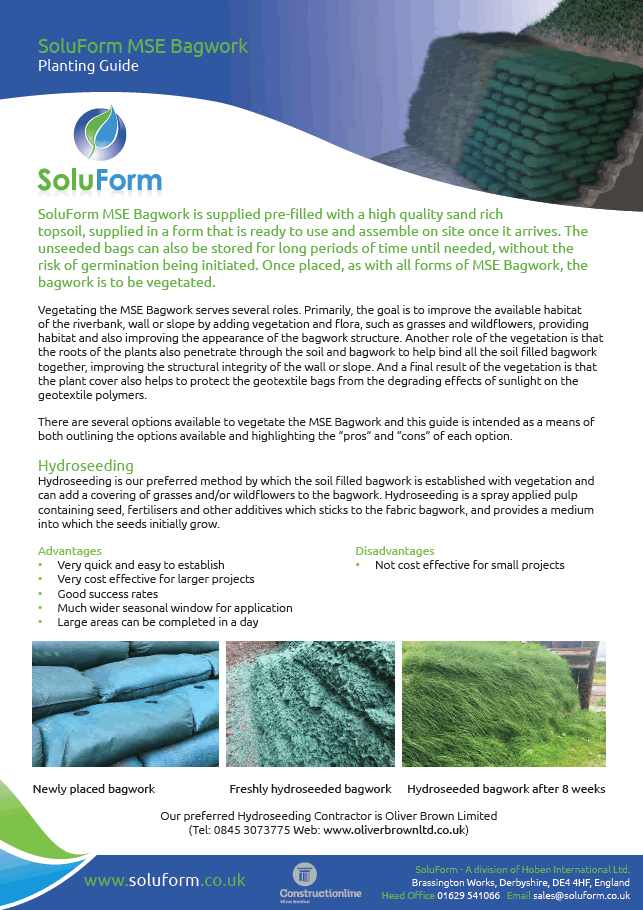

Hydroseeding is often used as a way of easily and quickly establishing vegetation on MSE bagwork, particularly on unseeded prefilled bagwork and typically a hydroseeding contractor would ordinarily be engaged to do this.

Other forms of planting include adding live plants to the bagwork or adding live stakes etc. along the front face of the bagwork. Live planting can be a good way of speeding up the establishment of vegetation and it can also improve the biodiversity of any planted scheme.

Planting

Ultimately the goal in all MSE Bagwork projects is to establish planting on/in the bagwork, to establish growth and increase biodiversity to the bagwork structure. Rooting within and between the bagwork helps to hold all the soil filled bags together, as well as helping protect the fabric bags long term.

The establishment of planting on prefilled bagwork can can be achieved in a number of ways including any one or a combination of the following methods:

- Hydroseeding by a commercial Hydroseeding Contractor – this involves spraying the bagwork following placing with a seed/mulch mix that then germinates and grows on the bagwork.

- Live planting after placement – Plugs and plants are inserted into the gaps and joints between the bags, which then establish and cover the bagwork.

- As with other forms of MSE Bagwork, other options for planting are available. These may include live stake planting, covering with topsoil and seeding/seeded geotextiles on slopes, covering with turf or pre-vegetated wildflower mats. Some success with seeded fabric (Hytex) has also been achieved, though these need to be regularly watered.

Always bear in mind that any planted solution will require care and attention, particularly during the initial germinating and growing period, to achieve the best results. Any planted solution should be kept watered until it has established, to avoid it drying out. If this cannot be ensured, placement of the bagwork and planting should avoid sustained periods of dry hot weather. Regular maintenance and aftercare of the vegetated bagwork is often also required.

Planting Guidance Document

Download the PDF